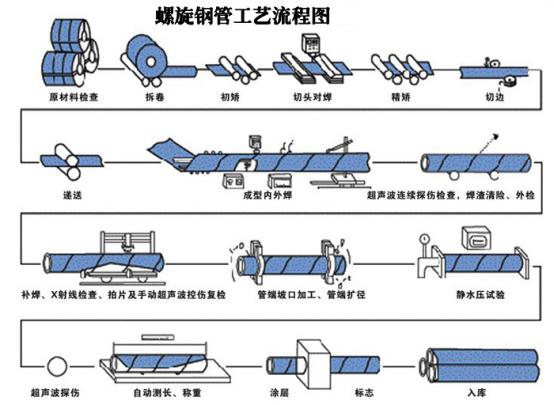

Pipe ea tšepe ea Spiralke hlobolisa coil e le thepa e tala, hangata e futhumatsang extrusion bōpa, othomathike habeli terata mahlakoreng ka tlas'a metsi arc tjheseletsa tshebetso welded spiral seam tšepe pipe phala mekhoa ea mantlha ea tlhahiso ke tse latelang:

Ts'ebetso ea tlhahiso ea phala ea tšepe ea spiral

1. Ts'ebetso ea boto e sa phutholohang: Ka mor'a ho kena moleng oa tlhahiso ea poleiti e sa phutholohang, tlhahlobo ea pele ea ultrasonic board e feletseng.

2. Leveling Milling: The bataletseng tšepe anvil mochini e le hore curl ea pele, 'me joale ka bohale mochini siloa bakeng sa mahlakoreng a mabeli siloa tšepe, e le ho kopana le ditlhoko tsa poleiti bophara, poleiti bohale parallelism le groove sebopeho.

3. ho bopa ho kuta: mohala oa tlhahiso ea poleiti ea tšepe haufi le moeli o ka ntle oa spiral curl ho kena ka har'a tube.

4. sekoa sa butt: ho cheselletsa arc ka mahlakoreng a mabeli ho sebelisa theknoloji e tsoetseng pele ho tjheseletsa pele, ho tjheseletsa ka hare, ho tjheseletsa ka ntle. Ion leoto sehiloeng ho tlhaloso bolelele tjheseletsa spiral phala tšebeliso joalo-joalo.

5. tlhahlobo ea pono: ke basebetsi ba litsebi le ba botekgeniki ho tse ling tsa litekanyetso tsa mantlha tse lokelang ho hlahlojoa.

6. The ultrasonic bofokoli lemoha: ka hare le ka ntle weld le weld mahlakoreng ka bobeli a thepa motheo 100% tlhahlobo.

7. X-ray ho lemoha: ka hare le ka ntle welds 100% X-ray indasteri TV hlahloba tsamaiso ea litšoantšo ho etsa bonnete ba hore tshebediso ya ho lemoha kutloisiso.

8. Teko ea khatello: spiral steel pipe hydrostatic test machine-by-root test ho netefatsa hore pipe ea teko ea khatello e finyella litekanyetso tse hlokahalang.

9. chamfering bataletseng hlooho: spiral tšepe phala tlhahlobo etsoa ka mor'a hore phala qetellong sebetsa, ho kopana le ditlhoko tsa phala qetellong beveling boholo.

10. Tlhahlobo ea ho qetela: tlhahlobo ea ultrasonic le X-ray hape 'me phala ea tšepe ea spiral e qetella tlhahlobo ea likaroloana tsa makenete, hlahloba hore na ho na le mathata le lipeipi tsa welding li qetella li na le bokooa.

11. ho tšoaea ka oli: phala ea tšepe ea spiral ka mor'a hore e fete e ne e tlotsoa ka oli ho thibela kutu, 'me ho latela litlhoko tsa mosebelisi bakeng sa ho tšoaea.

Nako ea poso: Jun-22-2022