Channel

A36 Steel Channel is a hot rolled, mild steel structural C shape with inside radius corners that is ideal for all structural applications, general fabrication, manufacturing and repairs. Steel Channel is widely used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, etc. It’s C-shape or U-shape configuration is ideal for added strength and rigidity over steel angle when your project’s load is vertical or horizontal. This steel shape is easy to weld, cut, form and machine with the proper equipment and knowledge. Metals Depot stocks hundreds of sizes of steel channel at wholesale prices in ready to ship precut and mill lengths or you can order just what you need custom Cut to Size in small or large quantity. A-36 Steel Channel is also available in a galvanized coated finish for long lasting corrosion protection.

|

Hot-rolled channel steel |

|||

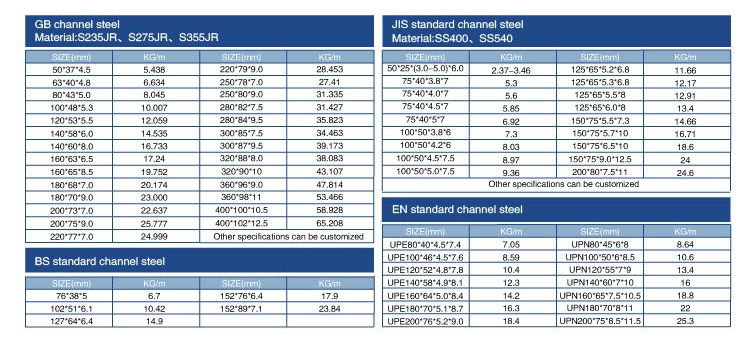

| Executive Standard | GB/T 707-1988 | JIS G 3192-2006 | DIN 1026-1:2000 |

| Steel Grade | Q235B | SS400 | S235JR |

| General Size | 5# 50*37*4.5mm - 40B 400*102*12.5mm | 5# 50*25*3mm – 200*80*7.5mm | UPN140- UPN200 |

| Length | 6m,10m,12m, or can follow customer request as 5.5m,5.8m to loading in container. | ||

| Advantages | 1. high quality2. high dimensional accuracy3. cost savings | ||

| Application | Building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc | ||

| Packaging | Professional export packaging or according to customer requirements. | ||

|

Cold bending channel steel |

|||

| General Size | width:10-400mm,thickness:1-16mm | ||

| Length | 6m,9m,12m, or can follow customer request as 5.5m,5.8m to loading in container. | ||

| Advantages | Make up for the specifications that hot-rolled channel steel cannot be produced. Specification and thickness can be processed according to customized size | ||

ASTM A53/ASTM A573/ASTM A283 Gr.D/BS1387-1985/GB/T3091-2001,

GB/T13793-92,ISO630/E235B/JIS G3131/JIS G3106

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 – 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 – 13 .0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

|

TOLERANCES OF A36 STEEL CHANNEL (+/-) |

||||||

|

Channel Size |

Depth of Channel |

Flange Width |

Straightness in 10 feet |

Lengths +/- |

Out of Square |

|

|

Custom Cut |

Standard |

|||||

|

1/2 to 1-1/2 |

1/32 |

1/32 |

1/4 |

1/16 |

1/4 |

1/32 |

|

1-1/2 to 3 |

1/16 |

1/16 |

1/4 |

1/16 |

1/4 |

1/32 |

|

3 to 7 |

3/32 |

1/8 |

1/4 |

1/8 |

1/4 |

1/32 |

|

7 to 14 |

1/8 |

1/8 |

1/4 |

1/8 |

1/4 |

1/32 |

|

over 14 |

3/16 |

1/8 |

1/4 |

1/8 |

1/2 |

1/32 |

|

Tolerance values provided herein are for informational purposes only and not guaranteed. |

||||||