Tee

Pipe Tee, Tee Fittings

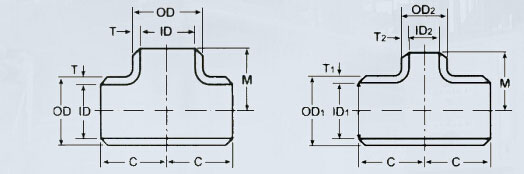

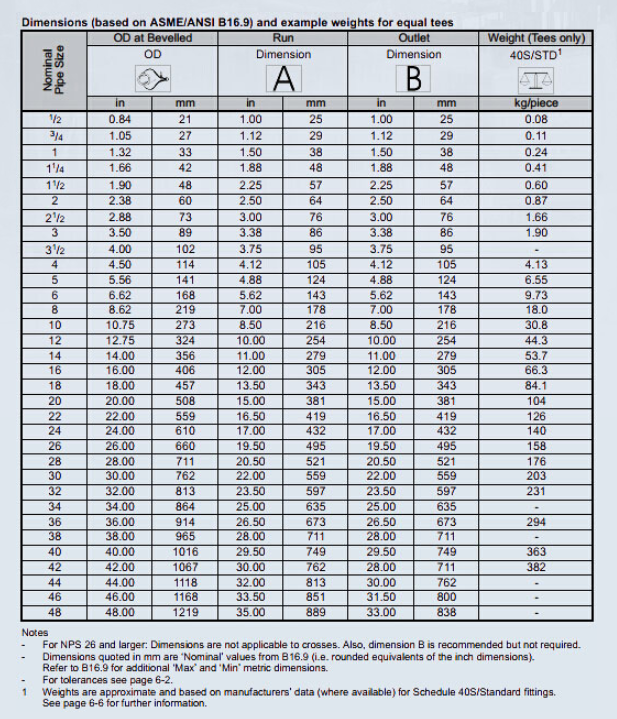

A tee is also called triplet,three way and “T” pieces and it can be used to either combine or split a fluid flow. Most common are tees with the same inlet and outlet sizes, but ‘reducing’ tees are available as well. it means the one or two ends are differ in dimension.due to thisdimension differ,the makes the tee fittings with the capacity to control the volume when requried.

Steel pipe tee has three branches that can change fluid direction. It has T-shaped or Y-shaped, and include Equal Tee and Reducing Tee (Reducer Tee). Steel tee is widely used in pipe networks for convey liquids and gases.

types of steel pipe tee:

According to branch diameters and functions there are:

Equal Tee

Reducing Tee (Reducer Tee).

According to connection types are:

Butt Weld Tee

Socket Weld Tee

Threaded Tee.

According to material types there are:

Carbon Steel Pipe Tee

Alloy Steel Tee

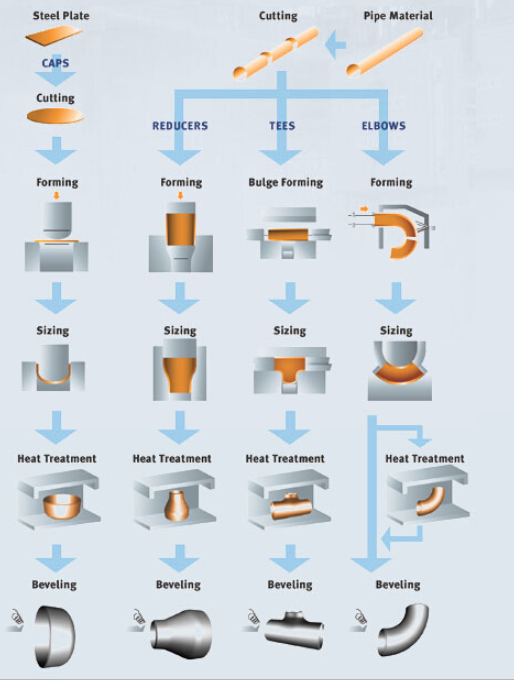

process

Carbon Steel Tee

Carbon steel tee material: ASTM A234 WPB, WPC; MSS SP-75 WPHY-42, WPHY-46, WPHY-52, WPHY-56, 60, 65 and 70.

ASME/ANSI B16.9 for butt weld tee fittings,

ASME/ANSI B16.11 for socket weld and threaded tee fittings.

Alloy Steel Tee

Alloy steel material: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91

Stainless Steel Tee

Stainless steel tee is widely used in chemical, health, food and other industries. Its advantages are applicable to different working environments and have good corrosion resistance.

Standards: ASTM A403 (Common Standard for stainless steel pipe fittings), ASTM A270 (Sanitary Tubing Standard)

Grade: TP 304, 304L, 316, 316L, 310, 317 and 321.

Light Oiling, Black Painting