Galvanized Seamless Pipe

Hot Dip Galvanizing Process

Material Inspection (Steel Pipe) --- Hanging --- De-greasing --- Rinsing --- Pickling --- Washing --- Dipping Fluxing --- Hot Air Drying --- Inside and Outside Hot-dipped Galvanizing Blow

--- Cooling --- Passivation and Rising --- Unloading --- Inspection and Trimming --- Type Identification --- Packaging and Storing and Transportation

| Commodity | Galvanized Seamless Pipe |

|

OD |

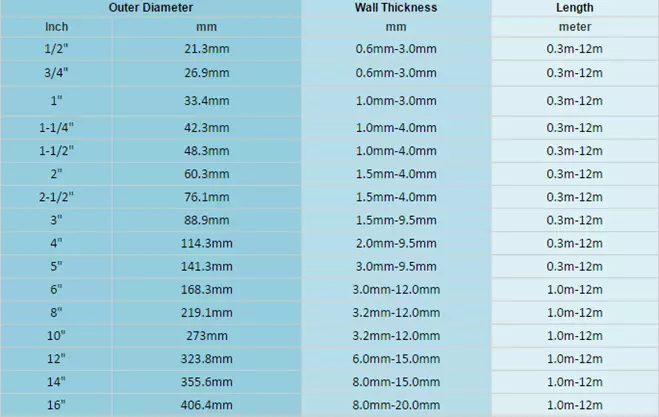

21.3mm ~ 406.4mm |

|

thickness |

0.5mm ~ 20mm |

|

length |

0.3mtr ~ 18mtr |

|

material |

Q195—Grade B, SS330, SPC, S185Q215—Grade C,CS Type B, SS330, SPHCQ235---Grade D, SS400, S235JR, S235JO, S235J2Q345---SS500, ST52 |

|

Standard |

GB/T13793-1992,GB/T14291-2006, GB/T3091- 1993,GB/T3092-1993,GB3640-88BS1387/1985,ASTM A53/A36,EN39/EN10219,API 5L,GB/T9711.1-99 etc |

|

zinc coating |

pre galvanized steel pipe: 60-150g/m2hot dipped galvanized steel pipe:200-400g/m2 |

|

application |

Widely used in Structure, Accessorize,Construction,Fluid transportation,machinery parts,the stressparts of the automobiletractor parts and so on |

|

Package |

1) Big OD: in bulk2) Small OD: packed by steel strips3) Plastic bags4) According to customer’s requirement |

|

advantage |

1. reasonable price with excellent quality2, abundant stock and prompt delivery3, rich supply and export experience, sincere service |

| Element Material |

Chemical Composition% |

Mechanical Property |

||||||

|

C% |

Mn% |

S% |

P% |

Si% |

Yield Point (Mpa) |

Tensile Strength (Mpa) |

Elongation (%) |

|

|

Q195 |

0.06-0.12 |

0.25-0.50 |

<0.050 |

<0.045 |

<0.30 |

>195 |

315-430 |

32-33 |

|

Q215 |

0.09-0.15 |

0.25-0.55 |

<0.05 |

<0.045 |

<0.30 |

>215 |

335-450 |

26-31 |

|

Q235 |

0.12-0.20 |

0.30-0.70 |

<0.045 |

<0.045 |

<0.30 |

>235 |

375-500 |

24-26 |

|

Q345 |

<0.20 |

1.0-1.6 |

<0.040 |

<0.040 |

<0.55 |

>345 |

470-630 |

21-22 |

Degreasing, pickling, cleaning, galvanizing, passivation

Before Painting

Preparation of painting specification involves understanding environmental factors, location of piping (indoor or outdoor), insulation requirements, operating and design temperatures. It may also involve local rules and regulations as well as availability of materials.

Painting Workflow

- Ensure all tests are performed on piping system before starting painting work.

- Clean painting surface to remove oils, grease, dirt.

- Ensure proper room temperature and humidity levels.

- Use hand tools, machine tools, shot blasters etc to clean surface as per relevant standards and project requirements.

- Apply primer within 4 hours of surface preparation.

- Apply paint coats after previous coats have dried up, as per instructions of paint manufacturer.

Components Requiring Painting

• Carbon steel ducts, furnaces and stacks require painting.

• All un-insulated equipments like columns, vessels, drums, heat exchangers, pumps, compressors, electrical panels, motors etc. require painting.

• All structural componets like steel members, platforms, ladders,handrails etc. required painting.

Types of Painting Methods

• Painting by Brush

• Painting by Air Spray Painting Machine

• Painting by Airless Spray Painting Machine

Surfaces that should not be painted.

Non-ferrous materials like Aluminium are not required to be painted. Also other surfaces like Valve Stems etc. Checkout this complete list of surfaces that should not be painted.

Characteristics of Piping Paint Material

Paint material used for painting pipes and equipments must adhere to certain requirements as per project specification .Check out these typical requirements for various types of primers and paints.

Typical Piping Painting Systems

Check out these combinations of typical piping painting systems which comprise of surface preparation, primer coats and top coats.

Humidity Requirements During Painting

Proper weather conditions surrounding the place of painting work is essential w.r.t. humidity levels and room temperature. Check out these humidity and temperature requirements.

Qualification Criteria for Painting Contractor

Painting contractor needs to posses these qualifications for good quality of painting work in time.

Inspection and Testing Procedure

Sound inspection and testing procedure must be in place to ensure good quality of painting work. Check out this article for complete information on inspection and testing procedure.