Carbon Steel Welded Pipe

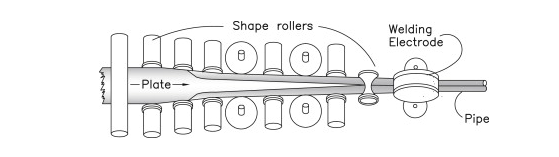

Butt-welded pipe is formed by feeding a hot steel plate through shapers that will roll it into a hollow circular shape. Forcibly squeezing the two ends of the plate together will produce a fused joint or seam. Figure 2.2 shows the steel plate as it begins the process of forming butt-welded pipe

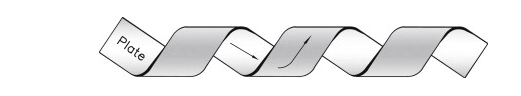

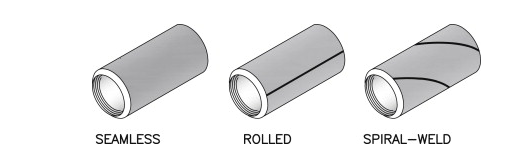

Least common of the three methods is spiral-welded pipe. Spiral-welded pipe is formed by twisting strips of metal into a spiral shape, similar to a barber’s pole, then welding where the edges join one another to form a seam. This type of pipe is restricted to piping systems using low pressures due to its thin walls. Figure 2.3 shows spiral-welded pipe as it appears before welding.

Each of the three methods for producing pipe has its advantages and disadvantages. Butt-welded pipe, for example, is formed from rolled plate that has a more uniform wall thickness and can be inspected for defects prior to forming and welding. This manufacturing method is particularly useful when thin walls and long lengths are needed. Because of the welded seam, however, there is always the possibility of defects that escape the numerous quality control checks performed during the manufacturing process.

As a result, the American National Standards Institute (ANSI) developed strict guidelines for the manufacture of pipe. Pressure Piping Code B31 was written to govern the manufacture of pipe. In particular, code B31.1.0 assigns a strength factor of 85% for rolled pipe, 60% for spiral-welded pipe, and 100% efficiency for seamless pipe.

Generally, wider wall thicknesses are produced by the seamless method. However, for the many low-pressure uses of pipe, the continuous welded method is the most economical. Seamless pipe is produced in single and double random lengths. Single random lengths vary from 16′-0″ to 20′-0″. Pipes 2″ and below are found in double random lengths measuring from 35′-0″ to 40′-0″.

| Carbon Pipe, Fittings and Flanges | |

| Form | Welded (ERW) and Seamless |

| Application | Fluid, Structural |

| Size Range | DN15 – DN600 |

| Grades | 250, 350 |

| Wall Thickness | Std Wt, XS |

| Fittings Type | Butt weld, Screwed & socket, Flanges, Black and Galvanised fittings to EN10241 (BS 1740) |

| Fittings Shape | Elbows, Tees, Reducers, Caps, Stub ends, Flanges (ANSI, Table E, D and H) |

| Processing | Cut-to-length, |

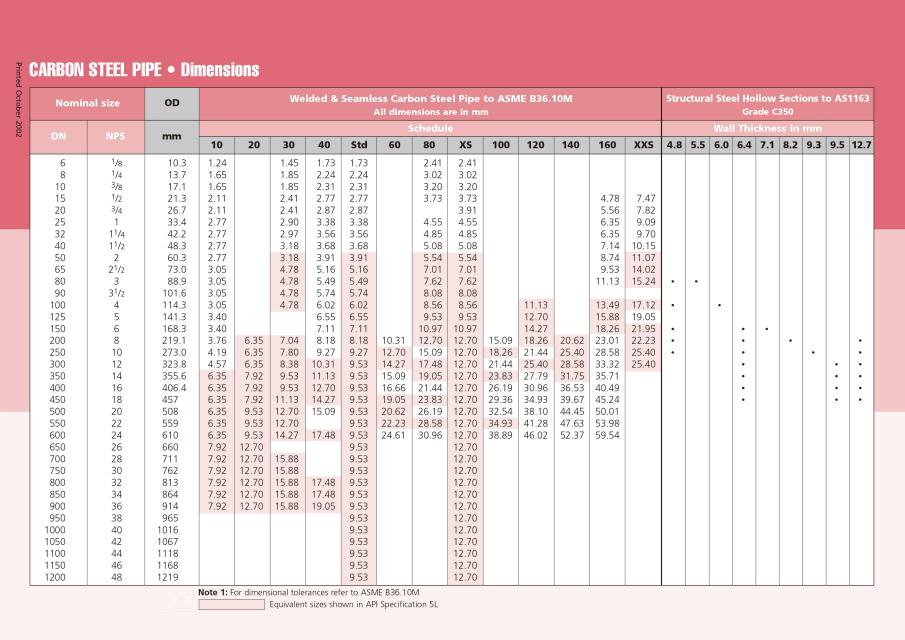

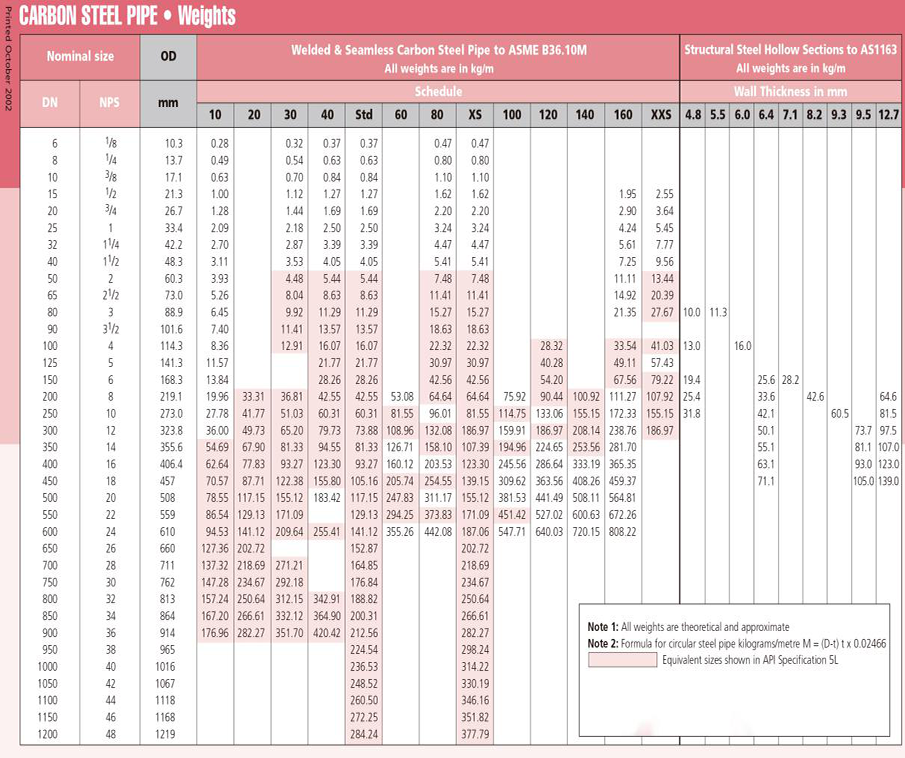

Carbon steel welded& seamless pipe dimensions and weights

Specification sheet for straight welded pipe

| Specification(mm) | OD(outer diameter) | wall thickness | weight | |

| 1/2 inch | 21.25 | 2.75 | 1.26 | |

| 3/4 inch | 26.75 | 2.75 | 1.63 | |

| 1 inch | 33.3 | 3.25 | 2.42 | |

| 11/4 inch | 42.25 | 3.25 | 3.13 | |

| 11/2 inch | 48 | 3.5 | 3.84 | |

| 2 inch | 60 | 3.5 | 4.88 | |

| 21/2 inch | 75.5 | 3.75 | 6.64 | |

| 3 inch | 88.5 | 4.0 | 8.34 | |

| 4 inch | 114 | 4.0 | 10.85 | |

| 5 inch | 140 | 4.5 | 15.04 | |

| 6 inch | 165 | 4.5 | 17.81 | |

| 8 inch | 219 | 6 | 31.52 | |

Specification table of folded spiral welded pipe

| specification | wall thickness | The weight per meter | National standard water pressure value | Nominal water pressure value | specification | wall thickness | The weight per mete | National standard water pressure value | Nominal water pressure value |

| 219 | 6 | 32.02 | 9.7 | 7.7 | 720 | 6 | 106.15 | 3 | 2.3 |

| 7 | 37.1 | 11.3 | 9 | 7 | 123.59 | 3.5 | 2.7 | ||

| 8 | 42.13 | 12.9 | 10.3 | 8 | 140.97 | 4 | 3.1 | ||

| 273 | 6 | 40.01 | 7.7 | 6.2 | 9 | 158.31 | 4.5 | 3.5 | |

| 7 | 46.42 | 9 | 7.2 | 10 | 175.6 | 5 | 3.9 | ||

| 8 | 52.78 | 10.3 | 8.3 | 12 | 210.02 | 6 | 4.7 | ||

| 325 | 6 | 47.7 | 6.5 | 5.2 | 820 | 7 | 140.85 | 3.1 | 2.4 |

| 7 | 55.4 | 7.6 | 6.1 | 8 | 160.7 | 3.5 | 2.7 | ||

| 8 | 63.04 | 8.7 | 6.9 | 9 | 180.5 | 4 | 3.1 | ||

| 377 | 6 | 55.4 | 5.7 | 4.5 | 10 | 200.26 | 4.4 | 3.4 | |

| 7 | 64.37 | 6.7 | 5.2 | 11 | 219.96 | 4.8 | 3.8 | ||

| 8 | 73.3 | 7.6 | 6 | 12 | 239.62 | 5.3 | 4.1 | ||

| 9 | 82.18 | 8.6 | 6.8 | 920 | 8 | 180.43 | 3.1 | 2.5 | |

| 10 | 91.01 | - | 7.5 | 9 | 202.7 | 3.5 | 2.8 | ||

| 426 | 6 | 62.25 | 5.1 | 4 | 10 | 224.92 | 3.9 | 3.1 | |

| 7 | 72.83 | 5.9 | 4.6 | 11 | 247.22 | 4.3 | 3.4 | ||

| 8 | 82.97 | 6.8 | 5.3 | 12 | 269.21 | 4.7 | 3.7 | ||

| 9 | 93.05 | 7.6 | 6 | 1020 | 8 | 200.16 | 2.8 | 2.2 | |

| 10 | 103.09 | 8.5 | 6.7 | 9 | 224.89 | 3.2 | 2.5 | ||

| 478 | 6 | 70.34 | 4.5 | 3.5 | 10 | 249.58 | 3.5 | 2.8 | |

| 7 | 81.81 | 5.3 | 4.1 | 11 | 274.22 | 3.9 | 3 | ||

| 8 | 93.23 | 6 | 4.7 | 12 | 298.81 | 4.2 | 3.3 | ||

| 9 | 104.6 | 6.8 | 5.3 | 1220 | 8 | 239.62 | - | 1.8 | |

| 10 | 115.92 | 7.5 | 5.9 | 10 | 298.9 | 3 | 2.3 | ||

| 529 | 6 | 77.89 | 4.1 | 3.2 | 11 | 328.47 | 3.2 | 2.5 | |

| 7 | 90.61 | 4.8 | 3.7 | 12 | 357.99 | 3.5 | 2.8 | ||

| 8 | 103.29 | 5.4 | 4.3 | 13 | 387.46 | 3.8 | 3 | ||

| 9 | 115.92 | 6.1 | 4.8 | 1420 | 10 | 348.23 | 2.8 | 2 | |

| 10 | 128.49 | 6.8 | 5.3 | 14 | 417.18 | 3.2 | 2.4 | ||

| 630 | 6 | 92.83 | 3.4 | 2.6 | 1620 | 12 | 476.37 | 2.9 | 2.1 |

| 7 | 108.05 | 4 | 3.1 | 14 | 554.99 | 3.2 | 2.4 | ||

| 8 | 123.22 | 4.6 | 3.6 | 1820 | 14 | 627.04 | 3.3 | 2.2 | |

| 9 | 138.33 | 5.1 | 4 | 2020 | 14 | 693.09 | - | 2 | |

| 10 | 153.4 | 5.7 | 4.5 | 2220 | 14 | 762.15 | - | 1.8 |

Lightly oiled, Hot dip galvanized, Electro

galvanized, Black, Bare, Varnish coating/Anti rust oil,

Protective Coatings