ASTM A335 Steel Pipe

| Product Name | Alloy Steel Pipe |

| Material | Alloy Steel |

| Pipe Length | Single Random Length and double Random Length.SRL:3M-5.8M DRL:10-11.8M or As clients requested length |

| Size | Size 1/4” to 24” Outside Diameter 13.7 mm to 609.6 mm |

| Wall thickness | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

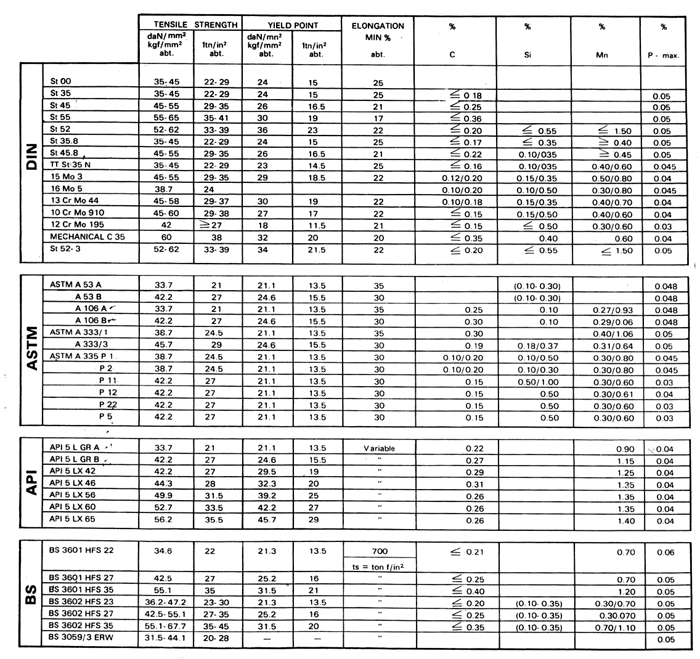

| Standard | ASTM A 335 Grade P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Grade 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr Mo V 121.BS 3059 Grade 243, 620-460, 622-490, 629-470, 629-590, 762.

JISG3458/G3462/3467 and DIN17175-79. |

| Applications | 1.Fluid pipe 2. Power Plant 3. Structure pipe 4. High and low pressure Boiler tube 5. Seamless steel tubes for petroleum cracking 6. Conduit pipe 7. Scaffolding pipe pharmaceutical and ship building etc |

| Certificate | ISO/PED/TUV/SGS/LR/BV |

| Main Market | Asia, Middle East, Europe, America, Africa, Australia, etc |

Chemical Composition(%):

|

Grade |

UNS Designation |

Composition, % |

|||||||

|

Carbon |

Manganese |

Phosphorus, |

Sulfur |

Silicon |

Chromium |

Molybdenum |

Others |

||

|

max |

max |

||||||||

|

P1 |

K11522 |

0.10–0.20 |

0.30–0.80 |

0.025 |

0.025 |

0.10–0.50 |

— |

0.44–0.65 |

— |

|

P2 |

K11547 |

0.10–0.20 |

0.30–0.61 |

0.025 |

0.025 |

0.10–0.30 |

0.50–0.81 |

0.44–0.65 |

— |

|

P5 |

K41545 |

0.15 max |

0.30–0.60 |

0.025 |

0.025 |

0.50 max |

4.00–6.00 |

0.45–0.65 |

— |

|

P9 |

S50400 |

0.15 max |

0.30–0.60 |

0.025 |

0.025 |

0.25–1.00 |

8.00–10.00 |

0.90–1.10 |

— |

|

P11 |

K11597 |

0.05–0.15 |

0.30–0.60 |

0.025 |

0.025 |

0.50–1.00 |

1.00–1.50 |

0.44–0.65 |

— |

|

P12 |

K11562 |

0.05–0.15 |

0.30–0.61 |

0.025 |

0.025 |

0.50 max |

0.80–1.25 |

0.44–0.65 |

— |

|

P15 |

K11578 |

0.05–0.15 |

0.30–0.60 |

0.025 |

0.025 |

1.15–1.65 |

— |

0.44–0.65 |

— |

|

P21 |

K31545 |

0.05–0.15 |

0.30–0.60 |

0.025 |

0.025 |

0.50 max |

2.65–3.35 |

0.80–1.06 |

— |

|

P22 |

K21590 |

0.05–0.15 |

0.30–0.60 |

0.025 |

0.025 |

0.50 max |

1.90–2.60 |

0.87–1.13 |

— |

|

P23 |

K41650 |

0.04–0.10 |

0.10–0.60 |

0.03 |

0.01 |

0.50 max |

1.90–2.60 |

0.05–0.30 |

V 0.20–0.30 |

|

Cb 0.02–0.08 |

|||||||||

|

B 0.0005–0.006 |

|||||||||

|

N 0.030 max |

|||||||||

|

Al 0.030 max |

|||||||||

|

W 1.45–1.75 |

|||||||||

|

P91 |

K91560 |

0.08–0.12 |

0.30–0.60 |

0.02 |

0.01 |

0.20–0.50 |

8.00–9.50 |

0.85–1.05 |

V 0.18–0.25 |

|

N 0.030–0.070 |

|||||||||

|

Ni 0.40 max |

|||||||||

|

Al 0.04 max |

|||||||||

|

Cb 0.06–0.10 |

|||||||||

|

P92 |

K92460 |

0.07–0.13 |

0.30–0.60 |

0.02 |

0.01 |

0.50 max |

8.50–9.50 |

0.30–0.60 |

V 0.15–0.25 |

|

N 0.03–0.07 |

|||||||||

|

Ni 0.40 max |

|||||||||

|

Al 0.04 max |

|||||||||

|

Cb 0.04–0.09 |

|||||||||

|

W 1.5–2.00 |

|||||||||

|

B 0.001–0.006 |

|||||||||

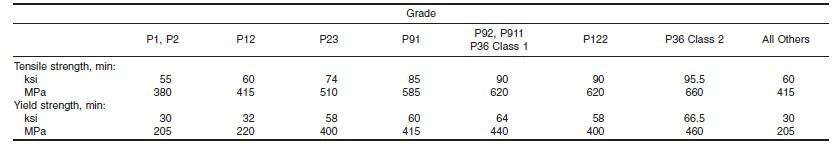

Mechanical Properties:

Black coating , oil/varnish ,FBE,2PE,3PE, galvanized etc Packaging Detail: Packing in bundles or for the client’s requirement