Boiler Pipe

Boiler tubes is a one of seamless pipe. Manufacturing methods is the same as seamless tube, but it has the stringent requirements for manufacture of steel pipes. According to the temperature level,boiler tube is divided into general boiler tubes and high pressure boiler tube.

Production methods:

① general boiler tube temperature is below 450 ℃, using hot-rolled pipe or cold drawn tube manufacture steel pipe.

② high-pressure boiler tube is used often in conditions of high temperature and high pressure pipe, the effect of high temperature flue gas and water vapor, oxidation and corrosion. Steel pipe with high rupture strength, high resistance to oxygen corrosion and have good organizational stability.

Boiler tubes purposes:

① general boiler tubes is mainly used to manufacture water wall tubes, tubes in boiling water and super heated steam pipe, super heated steam locomotive boiler tubes, large and small smoke pipe and pipe arch brick.

② high-pressure boiler tube is mainly used to manufacture high pressure and ultra-high pressure boiler super heater tubes, reheat tubes, airway, the main steam pipe.

Category:

General boiler tubes and high pressure boiler tube boiler tubes is exposed to high temperature performance. Boiler tubes in general, or high-pressure boiler tubes according to their use can be divided into a variety of steel pipe.

Standards and material for steel pipe is available at carbon, alloy, and stainless steel material.

Carbon steel: ASTM/ASME A/SA 106, ASTM A179, ASTM A192, ASTM/ASME A/SA 210, ASTM A333 Gr 1, 6,7 to Gr 9,

Alloy steel: ASTM/ASME A/SA 213 T1, T2, T5, T9, T11, T12, T22, T91, T92; ASTM A335 P1, P2, P5, P9, P11, P12, P22, P91, P92

Stainless Steel: ASTM A268, ASTM A213, TP304/L, TP316/L, 310S,309S,317,317L,321,321H, and duplex stainless steel material etc.

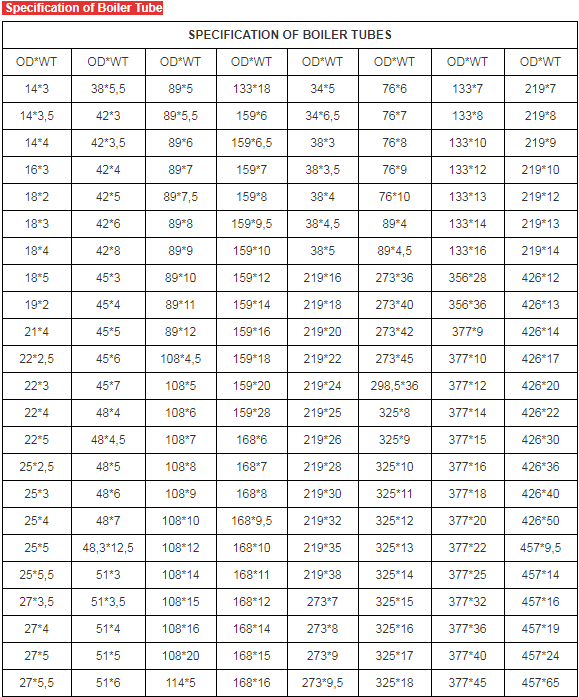

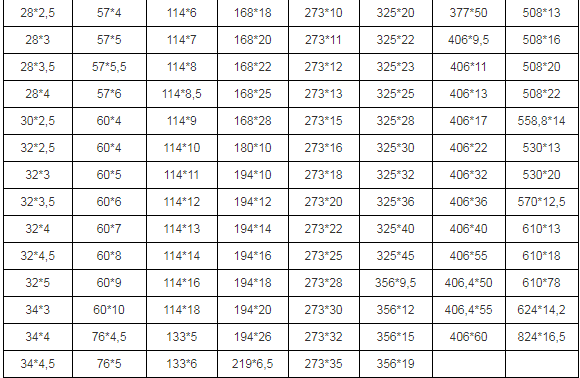

Common Sizes: OD from 6mm to 1240mm, thickness from 1mm to 50mm

Types: Straight boiler pipe, and U boiler steel pipe for tube exchanger bundle.

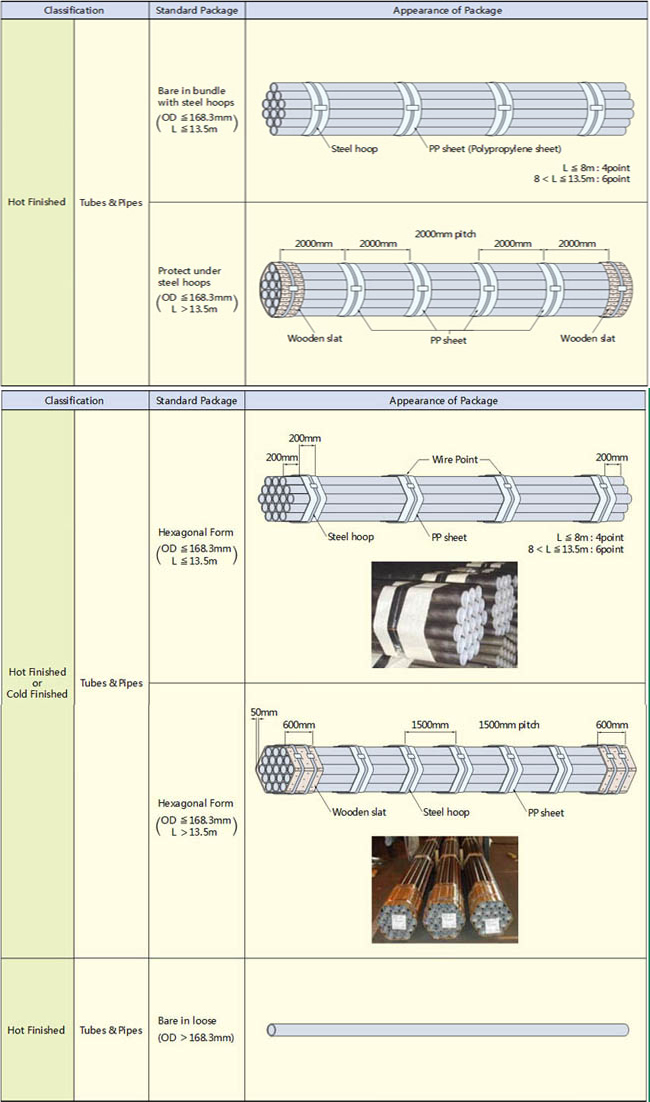

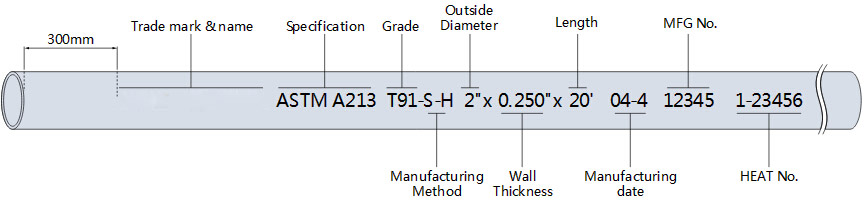

These standards specify the classification, size, shape, weight and allowable deviation, technical requirements, inspection and test, packaging, marking and quality certificate of seamless steel tubes for boiler.

Standards:

GB(Chinese National standards)

(2)GB 5310: Seamless steel tube for high pressure boiler

(3)GB 13296: Seamless steel tubes for boilers and heat exchangers

(4)GB 6479: Seamless steel tubes for high-pressure chemical fertilizer equipment

(5)GB 9948: Seamless steel tubes for petroleum cracking

ASME(American society of mechanical engineers)

(2)ASME SA-192M: Seamless Carbon Steel Boiler Tubes for High Pressure

(3)ASME SA-209M: Seamless carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes

(4)ASME SA-210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

(5)ASME SA-213M: Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes

(6)ASME SA178: Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater

ASTM(Chinese National standards)

(2)SA213-T2: ASME SA213 T2 has allowable stresses listed up to 1000F in the ASME Boiler Code.

(3)SA213-T9

(4)SA213-T12: Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, Heat-Exchanger Tubes.

(5)SA213-T11: The tubes are used in heat exchangers, super heaters and in boilers.

(6)SA213-T22: ASM T22 Boiler Tube is a high temperature tolerance tube that is used in acidic and corrosive environments such as the hydrochloric processing and in aluminum chloride catalyst involving applications.

(7)ASTM A 106M: Seamless Carbon Steel Pipe for High-Temperature Service

(8)ASTM A192M: Seamless Carbon Steel Boiler Tubes for High Pressure

(9)ASTM A210M: Seamless Medium-carbon Steel Boiler and Superheater Tubes

(10)ASTM A 335M: Seamless ferritic alloy-steel pipe for high-temperature servic

EN 10216-2 : Seamless steel tubes for pressure purposes

JIS

(1)JIS G3461: Carbon steel boiler and heat exchanger tubes

(2)JIS G3462: Alloy steel boiler and heat exchanger tubes

(3)JIS G3463: Stainless Steel for Boiler and Heat Exchanger Tubes

STAINLESS STEELS

SA213-T304:– The SA 213 Tp 304 Material consists of 18% chromium and carbon, manganese, phosphorus, sulfur, silicon and nickel in the composition.

SA213-T316: – SA213 TP316 Tube is a material standard for heat exchanger tubes that are made from 316 austenitic stainless steel.

SA213-TP321 & 347– SA213 TP321 is a specification of heat exchanger tubes that are made from the 321 austenitic stainless steel.

Bare, Lightly Oiled, Black/Red/Yellow Painting, Zinc/Anti-corrosive Coating

Standard Marking