News

-

Large diameter thick wall seamless steel pipe details

Large-diameter thick-walled seamless steel pipes are made from steel ingots or solid round steel that are perforated into capillary tubes and then hot-rolled. Large-diameter thick-walled seamless steel pipes play an important role in my country’s steel pipe industry. According to incomplete...Read more -

The difference between seamless steel pipe and welded steel pipe

1. Seamless steel pipe is a long strip of steel with no seams around it and has a hollow cross-section. It is widely used as a steel pipeline for transporting fluids. Compared with solid steel, it is lighter in weight when the bending and torsion strength are the same. An economical cross-section...Read more -

What should we pay attention to when welding steel pipe

When welding steel pipes, you need to pay attention to the following matters: First, clean the surface of the steel pipe. Before welding, make sure the surface of the steel pipe is clean and free of oil, paint, water, rust, and other impurities. These impurities may affect the smooth progress of ...Read more -

Special thick wall seamless steel pipe details

1. Definition and characteristics of special thick-walled seamless steel pipes. Special thick-walled seamless steel pipes, as the name suggests, refer to seamless steel pipes whose wall thickness exceeds conventional standards. The wall thickness of this kind of steel pipe is usually more than 20...Read more -

What are the weld grade requirements for internal and external epoxy powder coated straight seam steel pipes

The weld grade requirements for internal and external epoxy powder-coated straight seam steel pipes are generally related to the pipe use and working environment. There will be corresponding requirements in engineering design and standard specifications. For example, for pipelines transporting co...Read more -

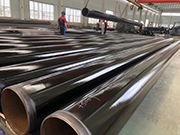

Process, characteristics, and applications of DN600 large diameter anti-corrosion spiral steel pipe

In today’s industrial field, DN600 large-diameter anti-corrosion spiral steel pipe is an important pipeline material and is widely used in petroleum, chemical industry, water treatment, and other fields. 1. Manufacturing process of DN600 large diameter anti-corrosion spiral steel pipe DN600...Read more