News

-

What are the reasons for uneven wall thickness of spiral seam submerged arc welded steel pipes

The spiral seam submerged arc welded steel pipe has a uniform wall thickness, looks good, is evenly stressed, and is durable. The spiral seam submerged arc welded steel pipe has uneven wall thickness and uneven stress on the steel pipe. The thin parts of the steel pipe will easily break. The unev...Read more -

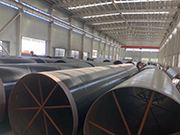

Why can 3pe anti-corrosion steel pipes be anti-corrosion

3PE anti-corrosion steel pipe means a PE steel pipe with three layers of anti-corrosion. 3pe anti-corrosion steel pipe is a kind of steel pipe with relatively good anti-corrosion properties and is widely used nowadays. What anti-corrosion materials does the structure of 3pe anti-corrosion steel p...Read more -

Spiral steel pipe cutting method

At present, the most common pipe cutting method used by spiral steel pipe manufacturers is plasma cutting. During cutting, a large amount of metal vapor, ozone, and nitrogen oxide smoke will be produced, which will seriously pollute the surrounding environment. The key to solving the smoke proble...Read more -

Introduction to the construction process of steel pipe piles

The purpose of steel pipe pile construction is to transfer the load of the upper building to the deeper soil layer with a stronger bearing capacity or to compact the weak soil layer to improve the bearing capacity and compactness of the foundation soil. Therefore, the construction of pipe piles m...Read more -

Common defects in the welding area of spiral steel pipes

1. Bubbles Bubbles mostly occur in the center of the weld bead, and hydrogen is still hidden inside the weld metal in the form of bubbles. The main reason is that the welding wire and flux have moisture on the surface and are used directly without drying. Also, the current is relatively high duri...Read more -

Anti-corrosion technology of anti-corrosion steel pipes

In recent years, the demand for steel pipe insulation pipes in various domestic industries has increased. The production technology of domestic steel pipe anti-corrosion factories has been relatively mature, and all kinds of anti-corrosion can be produced. Among them, 3PE anti-corrosion steel pip...Read more