News

-

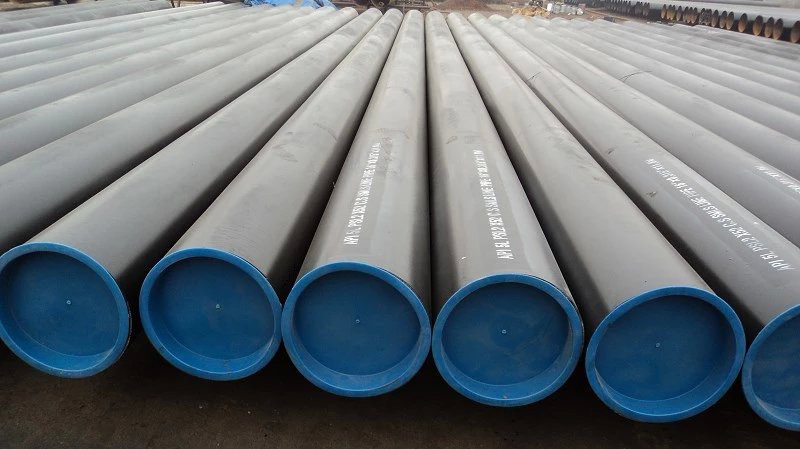

Line Pipes Steels

Line Pipes Steels Advantages: High strength, weight, and material-saving ability Typical application: large diameter pipes for transporting oil and gas Effect of molybdenum: prevents the formation of perlite after final rolling, promoting a good combination of strength and low-temperature durabil...Read more -

10 Ways to remove burrs from seamless steel tubes

Burs are ubiquitous in the metalworking process. No matter how advanced and sophisticated equipment you use, it will be born with the product. This is mainly due to the plastic deformation of the material and the generation of excessive iron filings at the edges of the processed material, especia...Read more -

What is OCTG?

What is OCTG? It includes Drill Pipe, Steel Casing Pipe and Tubing OCTG is the abbreviation of Oil Country Tubular Goods, it mainly refers to pipe products used in oil and gas production (drilling operations). OCTG tubing is typically manufactured based on API specifications or related standard s...Read more -

Stress of API 5CT Oil Casing in Oil Well

The stress on the API 5CT oil casing in the oil well: to ensure that the casing running into the well is continuous, not cracked or deformed, the casing is required to have a certain strength, enough to resist the external force it receives. Therefore, it is necessary to analyze the stress on the...Read more -

Types of Pipes

Types of Pipes Pipes are classified into two groups: seamless pipes and welded pipes, based on the manufacturing method. Seamless pipes are formed in one step during rolling, but bent pipes require a welding process after rolling. Welded pipes can be classified into two types due to the shape of ...Read more -

Six processing methods commonly used for seamless pipes

There are six main processing methods for seamless pipes (SMLS): 1. Forging method: Use a swage forging machine to stretch the end or part of the pipe to reduce the outer diameter. Commonly used swage forging machines include rotary type, connecting rod type, and roller type. 2. Stamping method: ...Read more