News

-

Basic requirements for anti-corrosive construction of welded steel pipes

1. The processed components and finished products shall not be disposed of externally until they are accepted by experience. 2. The burrs on the outer surface of the welded steel pipe, welding skin, welding knobs, spatters, dust and scale, etc. should be cleaned before removing rust, and loose ox...Read more -

Galvanized steel pipe

Galvanized steel pipe is a technique to improve the corrosion resistance of steel pipe and its beautiful decoration. Currently, the most commonly used method for galvanizing steel pipes is hot-dip galvanizing. The manufacturing process of seamless steel tubes can be divided into the basic types o...Read more -

Semless steel pipe price list Dec.2019

Read more -

Erw pipe manufacturing process

Erw pipe process mianly depends on a variety of products from raw materials to finished products, which need to go through a series of processes, completion of these processes requires a variety of machinery and equipment and welding, electrical controls, detection devices, these devices and devi...Read more -

Common Welding Defects

In the production process of steel welding, there will be the emergence of steel defects if the welding method is not correct. The most common defects are hot cracking, cold cracking, lamellar tearing, lack of fusion and incomplete penetration, stomata and slag. Hot cracking. It is produced duri...Read more -

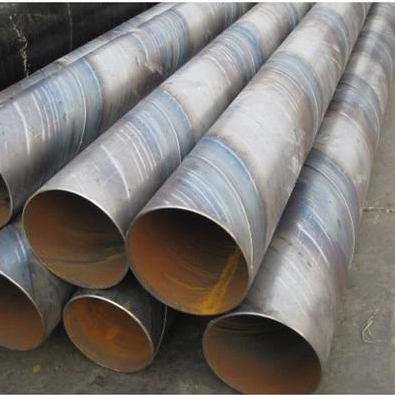

Decarbonized of spiral steel pipe

Life and surface decarburization of spiral pipe is a definite link, if the rear surface decarbonization, spiral strength and wear resistance will reduce direct impact on the spiral of life. If the carbon layer on the spiral steel pipe not clean, spiral surface layer hardness and wear resistance w...Read more