Industrial News

-

Duty coating

Heavy duty coating refers to the relatively conventional anti-corrosion coatings, the corrosion can in a relatively harsh environment applications, and has to achieve a longer protection than conventional anti-corrosion coating of a class of anti-corrosion coatings. Features of heavy-duty coating...Read more -

ASME B36.10 standards

ASME is the registered trademark of the American Society of Mechanical Engineers. Scope This standard covers the standardization of dimensions of welded and seamless wrought steel pipe for high or low temperatures and pressures. This word pipe is used as distinguished from tube to apply to tubula...Read more -

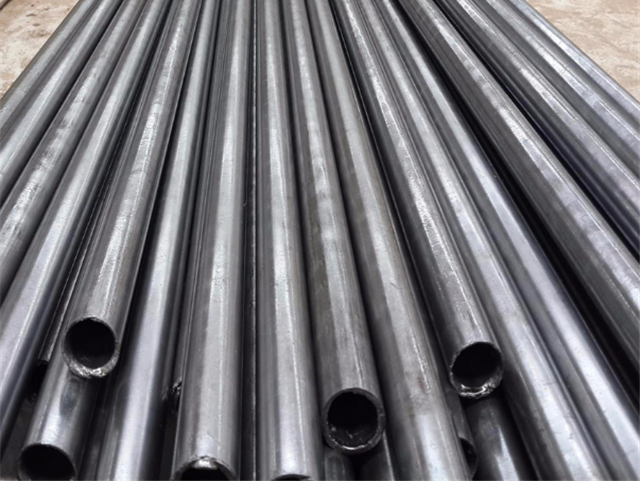

Application of high-precision cold drawn tubes in China

China’s high-precision cold drawn tube, the first to be widely used in the coal industry, and now it has been extended to the manufacturing engineering industry, oil, cylinder, cylinder and piston rod. Drawing quality, efficiency, more and more high, production is also increasing, with the ...Read more -

How to solve the deformation problem of spiral seam submerged arc welded steel pipe

The spiral seam submerged arc welded steel pipe is drilled in rotation and begins to enter the soft formation. Under the action of the tri-cone, the drill first produces elastic shear deformation of the stratum and then is removed under the pressure of the tri-cone. In the simulated environment, ...Read more -

Working principle of spiral seam submerged arc welded steel pipe

The spiral seam submerged arc welded steel pipe is drilled in rotation and begins to enter the soft formation. Under the action of the tri-cone, the drill first produces elastic shear deformation of the stratum and then is removed under the pressure of the tri-cone. In the simulated environment, ...Read more -

The difference between hot simmering elbow and cold simmering elbow

The process is as follows: After the straight pipe is cut, the induction loop is put on the part of the steel pipe to be bent through the bending machine, and the pipe head is clamped by the mechanical rotating arm, and the induction loop is passed into the induction loop to heat the steel pipe. ...Read more