News

-

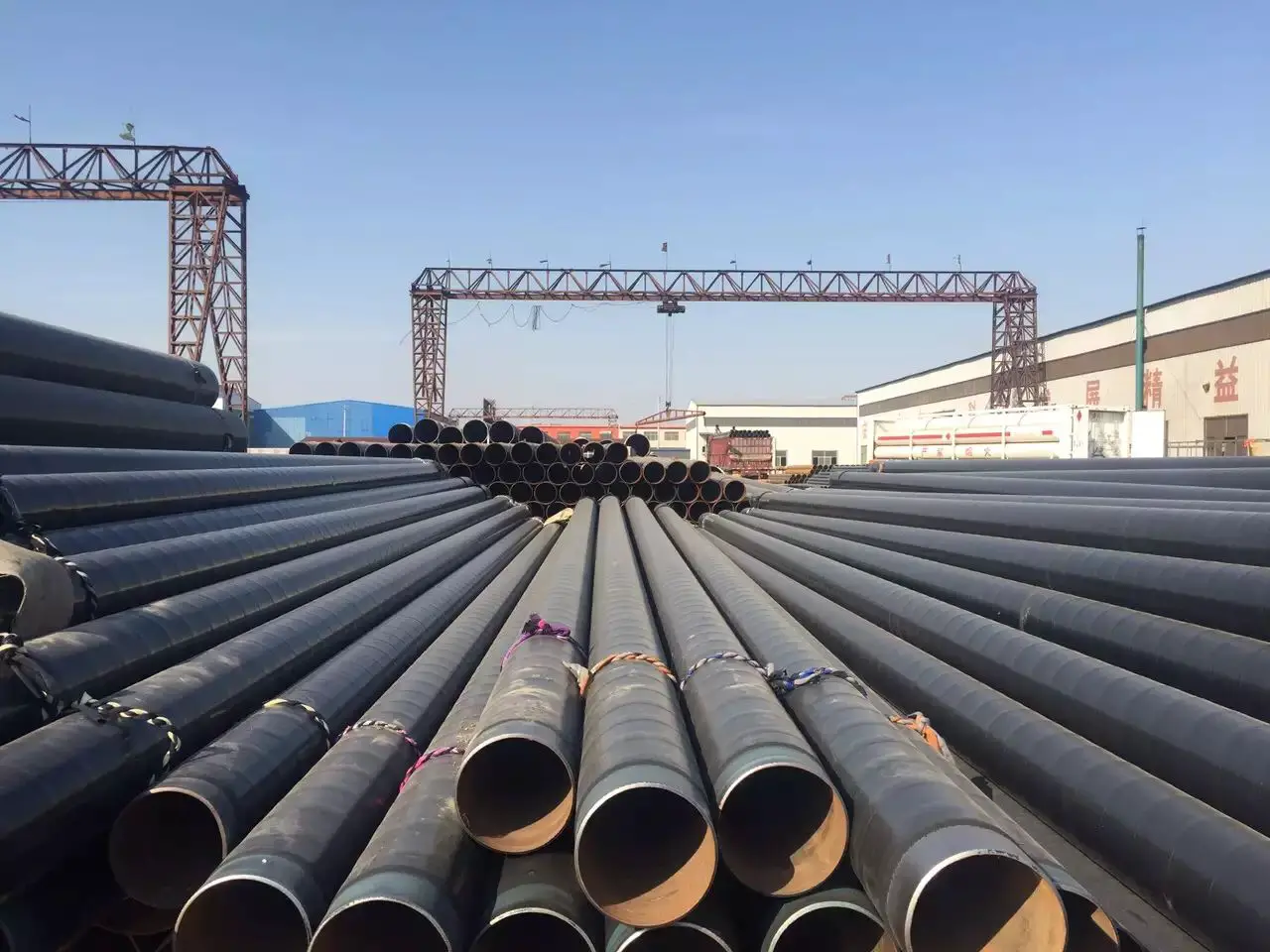

ERW Steel Pipe

Description: (1) welded pipe from steel plate welding into the round pipe, divided into high frequency resistance welded pipe (ERW welded pipe), straight seam arc welding pipe (LSAW), spiral welded pipe.Electrical engineering with “SC”, can be used as water gas pipe can also be used a...Read more -

Large-caliber Straight Seam Steel Pipe Production Process

1. Before molding work Raw materials that strip, wire, flux. We must go through rigorous physical and chemical testing before it is put. Strip head and tail docking, single or double wire submerged arc welding, in rolled steel by automatic submerged arc welding. 2. The molding process Electric co...Read more -

Continuous Rolling Production Process

Continuous rolling tube (hereinafter referred to as MPM) process is a mandrel refers to wear long capillary column continuously through a series arrangement rack, rolling and rolling method conforms to become rolling mother pipe size requirements. Its distinguishing feature is the large capacity,...Read more -

Alloy Seamless Pipe

Description: Alloy pipe is a kind of seamless steel pipe, its performance is much higher than that of general seamless steel pipe, because this type of steel pipe contains more Cr, its high temperature resistance, low temperature resistance, corrosion resistance performance is much better than o...Read more -

Seamless Steel Pipe

Description: Seamless steel pipe is a pipe material producing by a cold drawn process with high precision and high-quality finish. Due to the characteristics of high-precision, in precision machinery manufacturing, auto parts, hydraulic cylinders, construction (steel sleeve) industry has a very w...Read more -

Features of Hot-rolled Seamless Tube

After hot-rolled seamless steel tubes, the grain refinement of steel, the ingot destroy the cast structure, eliminate defects and microstructure of the resulting dense PIPE, improved mechanical properties. Air bubbles present before the steel pipe, cracks and loose, after hot rolling at high temp...Read more