News

-

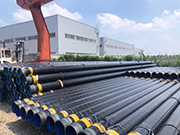

Spiral welding technology and details of large-diameter spiral welded steel pipes in industrial projects

Large-diameter spiral welded steel pipes are a type of steel pipe that has been widely used in recent years. Their main features are large diameter, high strength, and are suitable for long-distance transportation and transportation of high-pressure media. First, spiral welding technology of larg...Read more -

Details of plastic-coated straight seam steel pipes commonly used in industrial projects

Plastic-coated straight seam steel pipes are high-performance, high-strength steel pipe products that are widely used in various fields such as construction, water conservancy, petroleum, chemical industry, and electricity. It has the advantages of anti-corrosion, waterproof, wear-resistant, corr...Read more -

What are the uses and advantages of double-resistance plastic-coated steel pipes

First, the use of double-resistance plastic-coated steel pipes 1. Chemical industry: Double-resistance plastic-coated steel pipes are widely used in the chemical industry, such as conveying corrosive media such as acids, alkalis, and salts. Due to its excellent corrosion resistance, it can ensure...Read more -

Details of the characteristics and production applications of Q690MD straight seam welded steel pipes commonly used in industrial projects

Q690MD straight seam welded steel pipe is a high-strength low-alloy structural steel welded steel pipe, which is widely used in engineering machinery, bridge construction, shipbuilding, high-pressure vessels, and other fields. Its excellent mechanical properties and welding properties make it one...Read more -

Details of 347HFG stainless steel seamless pipes commonly used in industrial projects

Details of TP347HFG stainless steel seamless pipes 347HFG stainless steel seamless pipes, as a representative of high-performance stainless steel materials, play an important role in the industrial field, especially in high temperature, high pressure, and corrosive environments. 1. Commonly used ...Read more -

The surface of API 5L X60Q straight seam steel pipe is smooth and defect-free

API 5L X60Q straight seam steel pipe, as a high-quality pipe produced by the American Petroleum Institute standard API 5L, has shown excellent performance and reliability in the transportation fields of oil, natural gas, etc. with its smooth and defect-free surface. In the production process of A...Read more