Industrial News

-

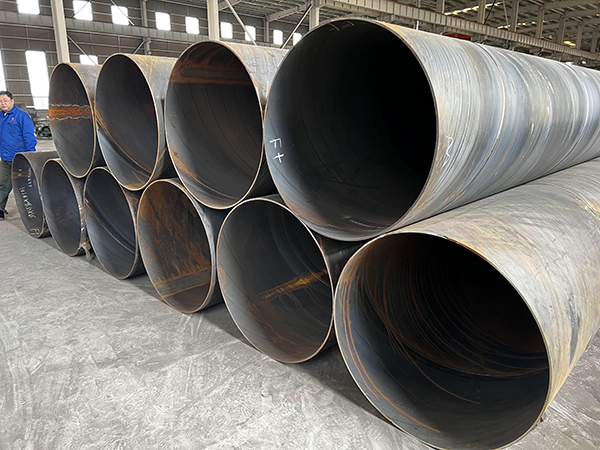

Large-diameter LSAW Steel Pipe Production Process

Large-diameter LSAW steel pipe production process mainly explained: 1. plate probe: used to manufacture large diameter submerged arc welded steel pipe joints straight after entering the production line, the first full-board ultrasonic testing; 2. Milling: Milling machine through the two-sided edg...Read more -

Tube Billet Heating Defects and Its Prevention

Hot-rolled seamless steel pipe from the tube to the product generally requires two heating, which perforated tube before and after heating and rolling blank pipe diameter at a given pre-heating; production of cold-rolled (pull) when the pipe requires the use of an intermediate annealing to elimin...Read more -

Spiral Weld Seam

Spiral weld seam has the following several types: 1. Spiral strip end weld: steel head that spiral weld on steel or steel weld head and tail; 2. Two spiral butt weld: spiral cut is to link the two together to form an annular weld; 3. Spiral tack welding: that is applied before the final welding. ...Read more -

Production of Cold Drawing Petroleum Cracking Tube

Production of cold drawing petroleum cracking tube can be cold-rolled, cold drawn, cold-drawn, cold-mix production. Using drawing process, a simple equipment, low investment, easy operation and maintenance and so on. But the drawback is the middle step of many, lumber rate. Using cold process equ...Read more -

Cause of the Welds in Trachoma

Spiral Pipe(ssaw steel pipe): by strip by roll forming machine, folding spiral direction, and then double-sided submerged arc welding is made through a capacitor. Spiral welded steel pipe production process, prone to leakage in many cases, such as welding and the wrong side. However, in these cas...Read more -

Advantages of Galvanized Pipes

Advantages of galvanized pipes is following below: Firstly, galvanized pipe after being hot dip galvanized surface can be protected, and inside the cavity of the pipe or any other coating the corner is difficult to enter, deepen the zinc can easily cover to the top, make whole galvanized pipe can...Read more