Products

-

Tubing

Process: ERW and Seamless Standard: API 5CT Certificate: Tubing: LTC, STC, BTC, VAM.Tubing: NUE, EUE. Out Diameter: Casing: OD 4 1/2″- 20″ (114.3mm-508mm) Tubing: OD 2 3/8″ – 4 1/2″ (60.3mm-114.30mm) Wall Thickness: 0. 205″- 0.635″ Length: R1(4.88mtr-7.62mtr), R2(7.62mtr-10.36mtr), R3(10.36mtr or longer) Steel Grade: H-40, J55, K-55, N-80, C-75, L-80, C-90, T-95, Q-125 Surface: Corrosion proofing water based paint End: Beveled, Square cut. And pipe pr... -

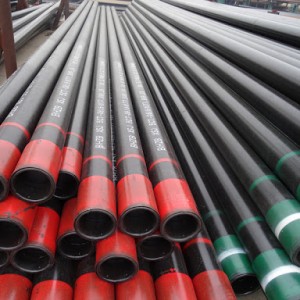

Casing

Casing is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore.It is inserted into a well bore and cemented in place to protect both subsurface formations and the well bore from collapsing and to allow drilling fluid to circulate and extraction to take place. Steel Casing Pipes have smooth wall & minimum yield strength of 35,000 psi. Well Casing serves as well sidewall. Standards and Technical Conditions for Supply:API Spec 5CT ISO1... -

Carbon Steel Seamless Pipe

Seamless Steel Pipe is made from a solid round steel ‘billet’ which is heated and pushed or pulled over a form until the steel is shaped into a hollow tube. The seamless pipe is then finished to dimensional and wall thickness specifications in sizes from 1/8 inch to 32 inch OD. Carbon Steel Seamless Pipes / Tubes Carbon steel is an alloy consisting of iron and carbon. The percentage of carbon in the steel affects the hardness, strength of elasticity and ductility of carbon steel. Seamless car... -

Carbon Steel Welded Pipe

Butt-welded pipe is formed by feeding a hot steel plate through shapers that will roll it into a hollow circular shape. Forcibly squeezing the two ends of the plate together will produce a fused joint or seam. Figure 2.2 shows the steel plate as it begins the process of forming butt-welded pipe Least common of the three methods is spiral-welded pipe. Spiral-welded pipe is formed by twisting strips of metal into a spiral shape, similar to a barber’s pole, then welding where the edges j... -

Stainless Seamless Pipe

Hardness : Stainless steel tubes are commonly used to measure the hardness of Brinell, Rockwell and Vickers. Brinell hardness Among the stainless steel pipe standards, Brinell hardness is the most widely used, and the hardness of the material is often expressed by the indentation diameter, which is both intuitive and convenient. However, it is not suitable for steel pipes of harder or thinner steel. Rockwell hardness: The stainless steel tube Rockwell hardness test is the same as the Brinell ... -

Stainless Welded Pipe

Characteristics First, the small-diameter stainless steel welded pipe is continuously produced online. The thicker the wall thickness, the greater the investment of the unit and the welding equipment, and the less economical and practical it is. The thinner the wall thickness, the lower the input-output ratio will be. The process of the product determines its advantages and disadvantages. Generally, the welded steel pipe has high precision, uniform wall thickness, and high brightness inside a...