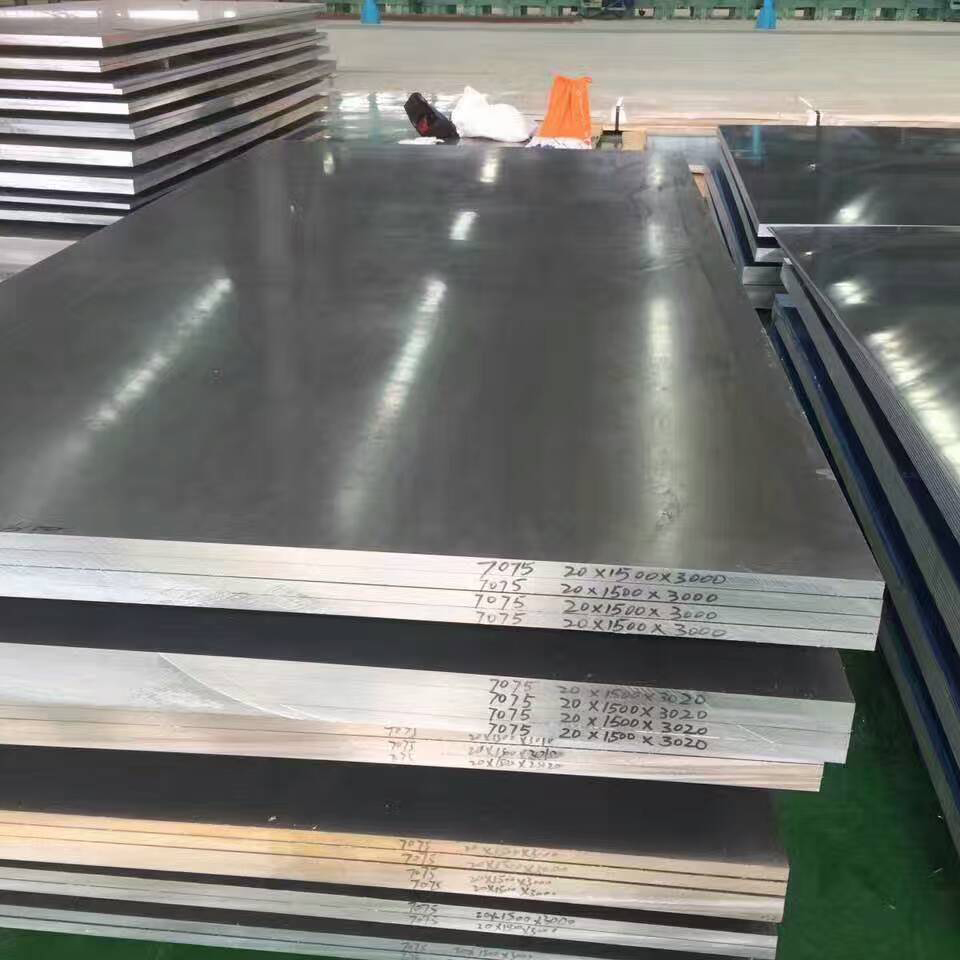

3003 Aluminum Plate&Sheet

3003 aluminum plate is a typical Al-Mn alloy, has good formability, corrosion resistance and weldability It is commonly used in the production of lightweight battery car shell, cooking utensils, food storage devices, cans on the transport equipment, Warehouse

3003 aluminium alloy & Aluminum Sheet 3003 Parameters

| Aluminum alloy model | Aluminum Sheet 3003 |

| Material state that can be produced | O,H12,H14,H16H18,H19,H22,H24 H26,H28,H112 |

| Thickness(mm) | 0.2-500 |

| Width(mm) | 20-2650 |

| Length(mm) | 500-16000 |

| Typical Application | Silo, antenna pot material, power battery case, car heat shield, etc. |

3003 Aluminum Sheet/Plate Advantage 3003-H14 Aluminum Sheet – (ASTM B209, QQ-A-250/2) Excellent weldability and formability, with good corrosion resistance makes 3003 Aluminum Sheet a popular and economical choice. 3003 Aluminum Sheet has a smooth, semi-shiny finish and is popular for many applications, including: fuel tanks, food & chemical handling, trailer siding & roofing, etc. Mill Finish – Not Polished Non-magnetic, Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-) The reason this metal is widely used is because it is affordable and strong. Compared to the 1100 series of alloys, 3003 aluminum is 20 percent stronger. This is due to it being integrated with 1.20 percent manganese. It is considered a pure aluminum and is frequently used in various applications, such as for storage tanks, tool boxes, walkways, truck beds, decorative trim and chemical equipment. It can also be used to create fan blades, siding, trailer components, kitchen equipment, cooking utensils and for signage applications.

3003 Aluminum Sheet Features: FEATURES: Excellent at resisting moisture and strong for its light weight. WORKABLE: Welds well with the proper equipment. Easy to Drill, Machine, Shear and Form. USES: Skinning Frames, Truck Beds, Tool Boxes, Trays, Drip Pans, Ornamental Work, Etc. 3003 aluminum has a lot of great characteristics that make it a popular choice. Other than being weldable and corrosion-resistant, it also has a surface that has a highly polished finish, making it an attractive choice. Although thin, it cannot be bent easily, instead requiring special tools to do so. Aluminum Sheet 3003 H14 Bare is an excellent choice for chemical equipment and general sheet metal projects due to its superior corrosion resistance and good workability. Aluminum 3003 H14 bare sheet works well in fabrication and decorative architectural uses because it is highly workable, formable, and weldable, while being capable of withstanding outdoor weather.

Application: With the excellent rust proof property, 3003 aluminum sheets are appropriate to be used in humid environments like refrigerators or air conditioners ducts, mechanical parts, or external packing. 3003 aluminum sheets are also widely applied to ships/vessels, vehicles, automobile and inserter welding assemblies, fireproof pressure vessels, refrigeration equipment, television tower, drilling equipment, transport and communication facilities, missile elements, plate armors and so on.

Performance:

1) Good corrosion resistance and moderate strength.;

2) Excellent weldability, formability, and machinability;

| PRODUCTNAME | ALLOYS NUMBER | TEMPER | THICKNESS(MM) | WIDTH(MM) | LENGTH(MM) | APPLICATION |

| 3003 Aluminum sheet /Plate | 3003 | O,H12,H14,H16H18,H19,H22,H24,H26,H28,H32,H34 H36,H38 | 0.2-7.0 | 100-2200 | 600-6000 | Power battery shell, phone shell and so on |

ASTM Standards:ASTM B209 and ASME SB209 ASTMB209–This specification covers aluminum and aluminum alloy flat sheet,coiled sheet, and plate in various alloys. 3003 aluminium alloy & Aluminum Sheet 3003 Chemical Composition

|

European Standard |

OLD |

WNr |

UNS |

ISO |

USA (AA) |

GERMANY (DIN) |

| AW-AlCu4Mg1 | AU4G1 | 3.0517 | A93003 | AlCu4Mg | 3003 | AlCuMg2 |

| ASME SFA5.3 (E3003) | ASTM B234 | ASTM B345 | AWS A5.3 (E3003) | QQ A-200/1 |

| ASTM B209 | ASTM B241 | ASTM B404 | MIL A-52174 | QQ A-225/2 |

| ASTM B210 | ASTM B247 | ASTM B483 | MIL E-15597 (MIL-3003) | QQ A-250/2 |

| ASTM B211 | ASTM B313 | ASTM B491 | MIL P-25995 | QQ A-430 |

| ASTM B221 | ASTM B316 | ASTM B547 | MIL S-12875 | QQ WW-T-700/2 |

| Metal Ratio of 3003 aluminum alloy (%) | |

| Si | 0.6 |

| Fe | 0.7 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Zn | 0.1 |

| Ti | 0.15 |

| Other | 0.1 |

| Al | remain |

Aluminium 3003 Sheet & Plates Equivalent Grades :

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlCu4Mg1 | AU4G1 | 3.0517 | A93003 | AlCu4Mg | 3003 | AlCuMg2 |

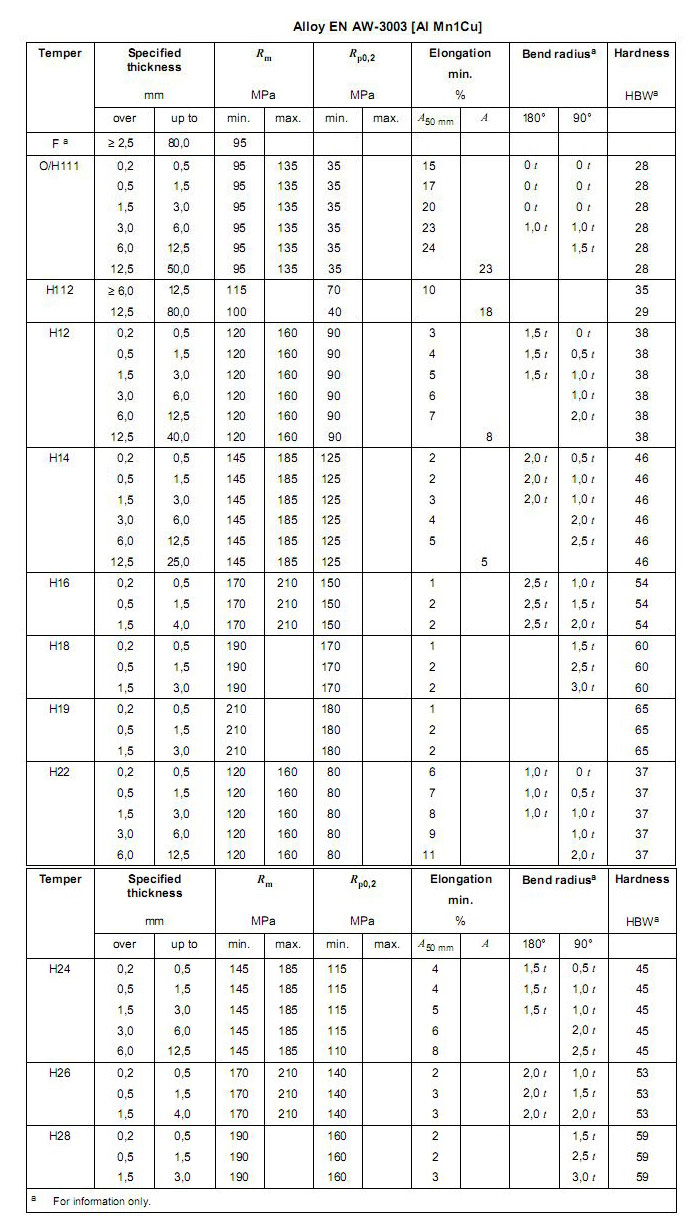

Mechanical Properties of Aluminium 3003 Plates

|

Properties |

Metric |

Imperial |

|

Tensile strength |

130 MPa |

18855 psi |

|

Yield strength |

125 MPa |

18130 psi |

|

Shear strength |

83 MPa |

12039 psi |

|

Fatigue strength |

55 MPa |

7977 psi |

|

Elastic modulus |

70-80 GPa |

10153-11603 ksi |

|

Poisson’s ratio |

0.33 |

0.33 |

|

Elongation |

10% |

10% |

|

Hardness |

35 |

35 |

|

Material |

Condition |

Tensile Strength (ksi min) |

Yield Strength (ksi min) |

Elongation % in 2″ 0.064 plate |

Min 90° Cold Bend Radius for 0.064″ Thick |

|

3003-0 plate 0.064″ thick |

3003-0 |

14-19 |

5 |

25 |

0 |

|

3003-H12 plate 0.064″ thick |

3003-H12 |

17-23 |

12 |

6 |

0 |

|

3003-H14 plate 0.064″ thick |

3003-H14 |

20-26 |

17 |

5 |

0 |

|

3003-H16 plate 0.064″ thick |

3003-H16 |

24-30 |

21 |

4 |

1/2 – 1 1/2 T |

|

3003- plate 0.064″ thick |

3003-H18 |

27 min |

24 |

4 |

1 1/2 -3T |

Standard export packing with wooden cases or wooden pallets as required by clients. Aluminum sheet, plate and coil products are wrapped by plastic films and brown papers. There are two kinds of packaging, which is eye to wall or eye to sky. Generally speaking, there are 2 tons in one package, and loading 18-22 tons in 1×20′ container, and 20-24 tons in 1×40′ container.