Industrial News

-

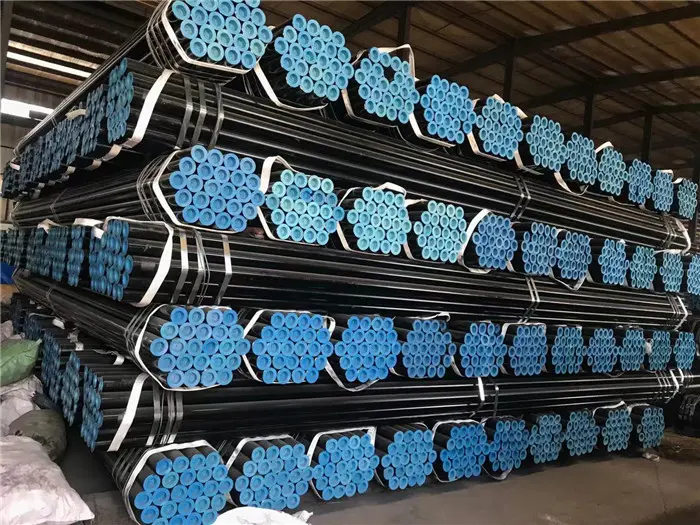

Steel Pipe Heat Nubmer

Heat number: it is a steel smelting furnace number of times with unique, traceability. Different mills have different numbering, but each furnace steel must be a number. Heat number is divided into furnace number and batch number, the furnace “means a furnace where the steel manufacturing p...Read more -

How to identify the quality of large diameter spiral welded pipe?

Spiral pipe, also known as spiral steel pipe or spiral welded pipe, is a low-carbon structural steel or low-alloy structural steel strip rolled into a tube blank at a certain helical angle (called a forming angle), also known as a spiral tube or a spiral body. The outer diameter of the spiral tub...Read more -

Common surface defects of seamless tubes

Common outer surface defects of seamless tubes (smls): 1. Folding defect Irregular distribution: If mold slag remains locally on the surface of the continuous casting slab, deep folding defects will appear on the outer surface of the rolled tube, and they will be distributed longitudinally, and &...Read more -

The main cooling bed types of spiral welded steel pipe production line

What are the main types of cooling beds in the spiral welded steel pipe production line? The following is introduced by HSCO carbon steel pipe manufacturers. 1. Single chain cooling bed The single-chain cooling bed mostly adopts a climbing structure. The cooling bed is composed of a forward trans...Read more -

Points of heating welding tube

Pipe processing step requires strict, in which the hot rolling process is very important process, in which to introduce the following precautions during the heating pipe. 1, the pipe must be able to feed one of those metal properties were a good understanding Before rolling, when the deforming fo...Read more -

Defect of Hot-rolled Seamless Steel Pipe

Defect of Hot-rolled Seamless Steel Pipe Separation Located on the inner surface of the steel pipe was vertical distribution, was raised helical, massive metal separation or break-like dissection. Straight inner flap Located on the inner surface of the steel pipe was vertical distribution, showin...Read more